Can polypropylene cartridges be used in fuel filtration?

In the realm of filtration technology, the selection of appropriate cartridges is crucial for ensuring the efficient and reliable operation of various systems. One question that often arises is whether polypropylene cartridges can be used in fuel filtration. As a polypropylene cartridge supplier, I am well - versed in the properties of polypropylene cartridges and their potential applications in fuel filtration, and I'll delve into this topic in detail.

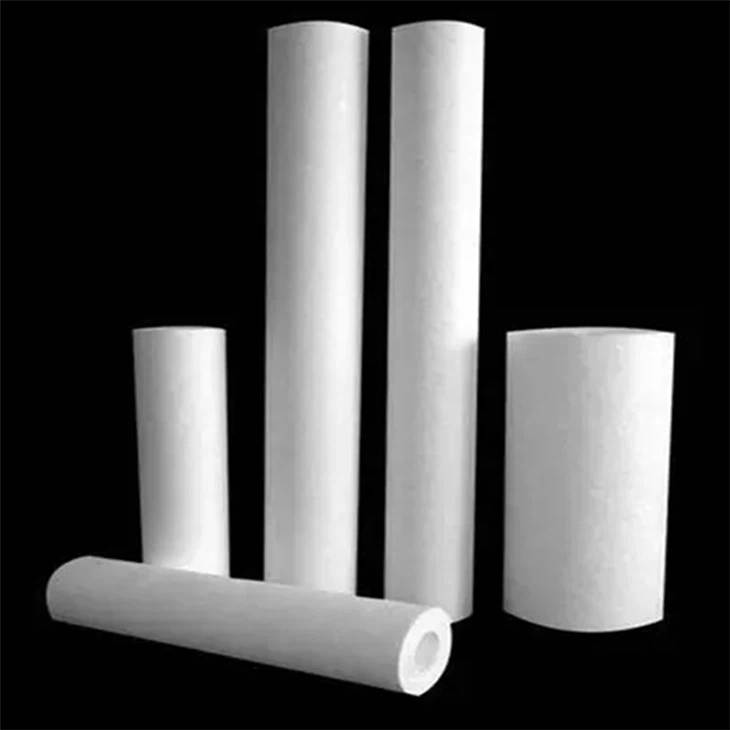

Properties of Polypropylene Cartridges

Polypropylene cartridges, also known as Polypropylene Cartridge, are widely recognized for their unique set of properties. First and foremost, polypropylene is a thermoplastic polymer that is highly resistant to chemicals. This chemical resistance makes it suitable for use in environments where it may come into contact with a variety of substances. In the context of fuel filtration, fuels can contain different additives, contaminants, and sometimes even trace amounts of water. Polypropylene cartridges can withstand the chemical composition of most common fuels, such as gasoline, diesel, and bio - fuels, without degrading or reacting with the fuel components.

Another significant property of polypropylene cartridges is their high mechanical strength. They can maintain their structural integrity under pressure, which is essential in fuel filtration systems where the fuel is often pumped through the filter at a certain pressure. This strength allows the cartridges to effectively trap contaminants without collapsing or being damaged, ensuring a consistent filtration performance over time.

Polypropylene cartridges also offer good filtration efficiency. They can be manufactured with different pore sizes, ranging from coarse to fine, depending on the specific filtration requirements. This flexibility in pore size enables them to capture a wide range of contaminants, from large particles like dirt and rust to smaller ones such as fine dust and sediment, which are commonly found in fuel.

Advantages of Using Polypropylene Cartridges in Fuel Filtration

One of the main advantages of using polypropylene cartridges in fuel filtration is their cost - effectiveness. Compared to some other types of filtration cartridges, polypropylene cartridges are relatively inexpensive to produce. This cost - benefit makes them an attractive option for both large - scale fuel filtration applications in industrial settings and smaller systems in automotive or marine engines.

The chemical resistance of polypropylene cartridges also means a longer service life. Since they are not easily affected by the chemicals in the fuel, they do not need to be replaced as frequently as some other types of cartridges. This reduces the overall maintenance cost and downtime associated with changing filters, which is especially important in continuous - operation fuel systems.

In addition, polypropylene cartridges are lightweight. This is beneficial in mobile applications such as vehicles and boats, where reducing weight can improve fuel efficiency and overall performance. The lightweight nature of polypropylene cartridges also makes them easier to handle during installation and replacement, reducing the physical effort required for maintenance.

Considerations for Using Polypropylene Cartridges in Fuel Filtration

While polypropylene cartridges offer many advantages for fuel filtration, there are also some considerations to keep in mind. One of the key factors is the compatibility with the specific type of fuel. Although polypropylene is generally resistant to most common fuels, there are some specialized fuels or fuel blends that may require additional testing to ensure compatibility. For example, some high - performance or alternative fuels may contain unique additives or chemical compounds that could potentially affect the performance of the polypropylene cartridge over time.

The operating temperature is another important consideration. Polypropylene has a certain temperature range within which it can function effectively. In extremely high - temperature environments, the mechanical properties of polypropylene may change, which could affect the filtration performance and the structural integrity of the cartridge. Similarly, in very cold temperatures, polypropylene may become more brittle, increasing the risk of cracking or damage.

The level of contamination in the fuel also matters. If the fuel contains a large amount of heavy contaminants or abrasive particles, the polypropylene cartridge may become clogged more quickly. In such cases, a pre - filtration step or a more robust cartridge design may be required to ensure continuous and efficient filtration.

Real - World Applications

Polypropylene cartridges are already being used in various fuel filtration applications. In the automotive industry, they are commonly used in fuel filters for cars, trucks, and motorcycles. These filters help to remove contaminants from the fuel before it reaches the engine, ensuring smooth engine operation and reducing the risk of engine damage. The cost - effectiveness and reliable performance of polypropylene cartridges make them a popular choice for automotive manufacturers and aftermarket suppliers.

In the marine industry, polypropylene cartridges are used in fuel filtration systems for boats and ships. The harsh marine environment often means that the fuel can be contaminated with saltwater, sand, and other debris. Polypropylene cartridges' chemical resistance and ability to capture a wide range of contaminants make them suitable for this application. They help to protect the marine engines from damage caused by contaminated fuel, ensuring the safety and reliability of the vessel.

Industrial fuel storage and distribution systems also benefit from the use of polypropylene cartridges. These systems handle large volumes of fuel, and the efficient removal of contaminants is essential to prevent damage to pumps, valves, and other equipment. Polypropylene cartridges can be integrated into these systems to provide cost - effective and reliable filtration solutions.

Comparison with Other Filtration Materials

When compared to other filtration materials such as cellulose or glass fiber, polypropylene cartridges have their own unique advantages. Cellulose cartridges are often less expensive but may have lower chemical resistance and mechanical strength. They are also more prone to swelling when exposed to water, which can affect their filtration performance. Glass fiber cartridges, on the other hand, offer high filtration efficiency but are generally more expensive and more brittle than polypropylene cartridges.

Polypropylene cartridges strike a balance between cost, performance, and durability. They can provide adequate filtration for most fuel applications while being more resistant to the chemical and physical stresses associated with fuel filtration.

Conclusion

In conclusion, polypropylene cartridges can indeed be used in fuel filtration. Their chemical resistance, mechanical strength, filtration efficiency, cost - effectiveness, and lightweight nature make them a viable option for a wide range of fuel filtration applications. However, it is important to consider factors such as fuel compatibility, operating temperature, and contamination levels to ensure optimal performance.

If you are in the market for high - quality PP Water Filter Cartridge for fuel filtration or other applications, we are here to help. Our company offers a wide range of polypropylene cartridges with different specifications to meet your specific needs. Whether you are an automotive manufacturer, a marine operator, or an industrial user, we can provide you with the right filtration solution. Contact us today to start a discussion about your filtration requirements and explore how our polypropylene cartridges can benefit your operations.

References

- "Filtration Handbook" by Andrew S. Mujumdar.

- "Fuel Systems and Components" published by the Society of Automotive Engineers.

- Industry reports on fuel filtration technologies and market trends.